Featured Connected Retail

EPA SNAP Rule: How and Why is it Important for Your Business?

Let’s talk refrigeration compliance in 2025— EPA refrigerant regulations are getting tougher, and non-compliance could hit you with $51,796 fines per violation.

Are your systems up to speed, or are you risking costly penalties?

The EPA SNAP program guides refrigerant choices for facility managers, HVAC/R professionals, and compliance officers in the US. With 70% of commercial systems needing upgrades by 2030, learning EPA SNAP refrigerant regulations is a must for operational success and sustainability.

Key takeaways

- The EPA SNAP program, combined with the AIM Act, drives the transition to low-GWP refrigerants

- Compliance requires selecting SNAP-approved refrigerants, managing leaks, and maintaining records

- Early adoption enhances cost stability and market competitiveness

- Facilio’s tools reduce compliance complexity and risks

What is the EPA SNAP program?

The EPA SNAP program (Significant New Alternatives Policy), created under Section 612 of the Clean Air Act, regulates substitutes for ozone-depleting substances (ODS) in refrigeration and other industries.

In facility operations, regulatory changes often arrive quietly but demand swift action. SNAP Rule 26 is one of those moments that marks a clear before-and-after for facility managers overseeing refrigeration systems.

The EPA SNAP program reviews refrigerants to determine their environmental and safety impacts, ensuring they meet stringent criteria like:

- Global Warming Potential (GWP)

- Ozone depletion

- Flammability

- Toxicity

- Overall environmental and health impact

Over the years, the EPA has used SNAP rules to approve safer alternatives and restrict the use of substances with high climate impact.

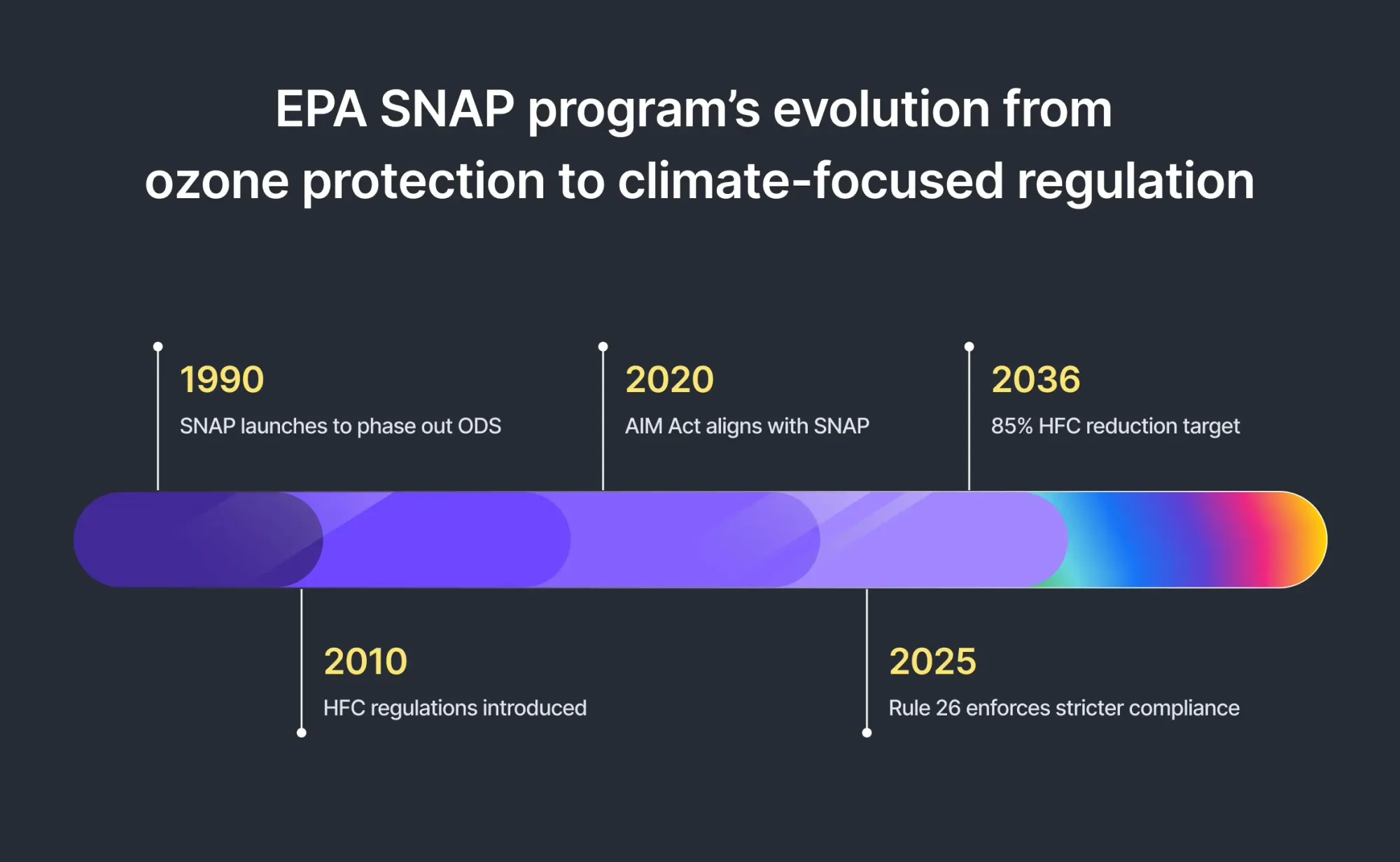

Initially focused on ODS phase-outs, the EPA SNAP program now aligns with the American Innovation and Manufacturing (AIM) Act to reduce hydrofluorocarbons (HFCs) by 85% over the next 15 years.

Core objectives of the SNAP program

- Evaluate alternatives: Assess new refrigerants for safety and environmental impact

- Identify acceptable substitutes: Publish lists of approved and prohibited EPA SNAP refrigerants for specific uses

- Protect human health: Ensure alternatives pose minimal risks to occupants and workers

- Safeguard the environment: Reduce climate and ecological impacts

- Enable transition: Support facility managers in adopting sustainable refrigeration solutions

Why is the SNAP Rule 26 critical for your facilities in 2025?

Compliance with the EPA SNAP program is non-negotiable in 2025.

For facility management professionals in America, here’s why SNAP Rule 26 is a priority:

a) Avoid Hefty Fines—Up to $51,796 Per Violation, Per Day

Non-compliance with EPA SNAP rules can lead to fines of $51,796 per violation per day, per EPA enforcement guidelines. For facilities with multiple refrigeration systems across sites, penalties can escalate rapidly, potentially reaching millions. The EPA may also issue stop-sale orders, halting operations using non-compliant refrigerants. Source.

b) Reduce Long-Term Financial Exposure and Retrofit Costs

Beyond fines, non-compliant systems increase costs:

- Higher maintenance expenses due to dwindling refrigerant supplies

- Increased insurance premiums

- Reduced equipment resale value

- Emergency retrofits costing up to $250,000 for a 50,000 sq. ft. facility

Proactive adoption of EPA SNAP refrigerants mitigates these risks and stabilizes budgets.

c) Protect Revenue by Staying Eligible for New Contracts

Corporate sustainability requirements are growing. Non-compliance with SNAP refrigerant regulations can disqualify your facilities from contracts with government agencies, retailers, or sustainability-focused clients. Demonstrating EPA SNAP program compliance enhances your competitive edge.

d) Demonstrate environmental leadership

Using SNAP-approved refrigerants showcases your commitment to environmental responsibility, a priority for occupants, investors, and employees. It also protects against price spikes of up to 500% for phased-out refrigerants like R22, ensuring cost stability for facility managers. Source

Key SNAP refrigerant regulations for 2025 compliance

Navigating EPA SNAP refrigerants and their regulations requires understanding approved lists, phase-out timelines, and compliance obligations critical for facility managers.

a) Approved and prohibited refrigerants

SNAP categorizes SNAP-approved refrigerants by application, with restrictions varying by use (e.g., retail refrigeration vs. chillers).

*Limited applications

**Requires leak detection, charge limits

***Strict charge limits (≤150g)

These EPA SNAP refrigerants are essential for compliance, with specific safety conditions for A2L and A3 classes to protect facility occupants.

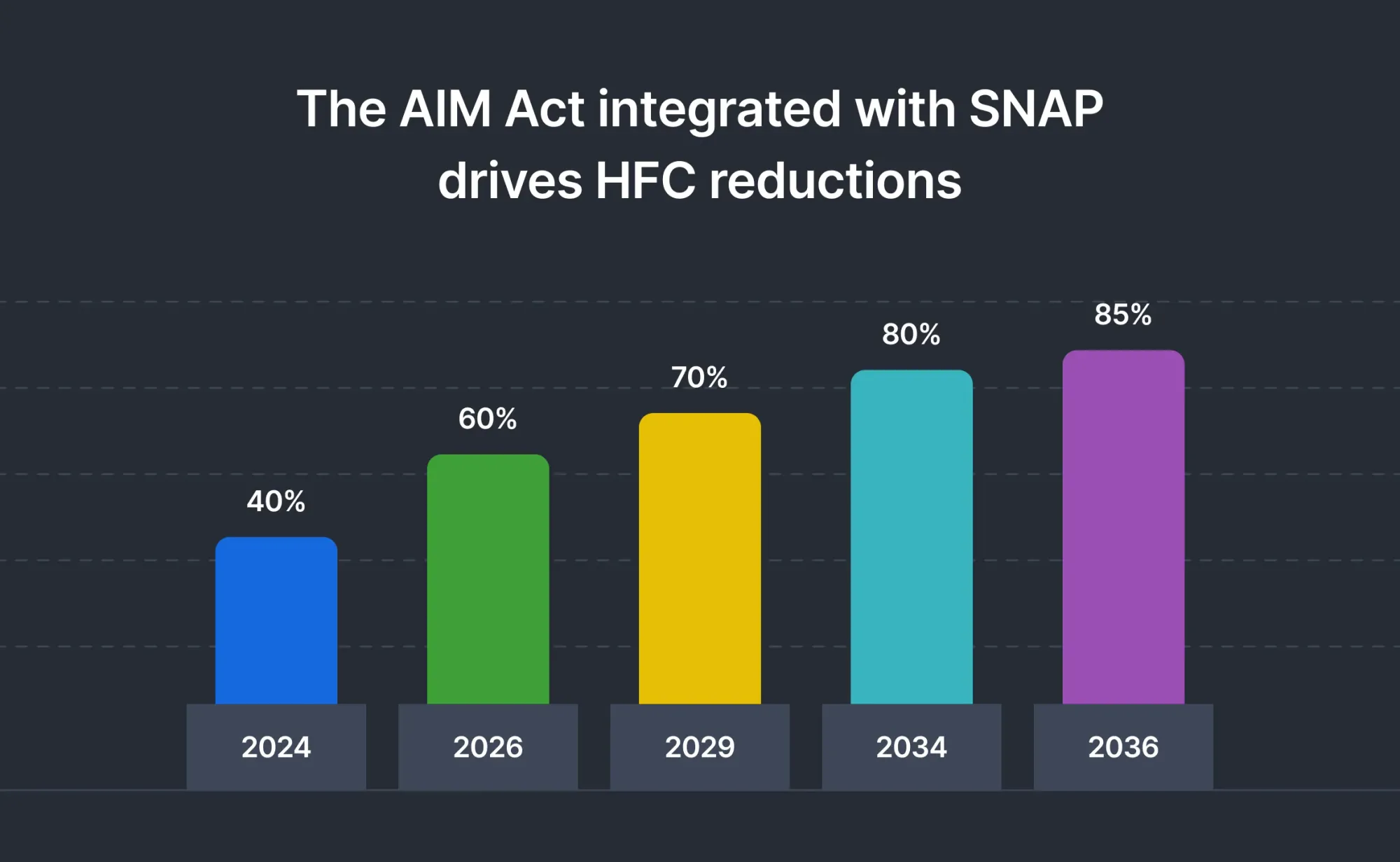

b) Meet critical HFC phase-out timelines through 2036

The AIM Act, integrated with SNAP, drives HFC reductions:

- 2024: 40% reduction

- 2026: 60% reduction

- 2029: 70% reduction

- 2034: 80% reduction

- 2036: 85% reduction

Source: EPA AIM Act overview.

Early transitions to SNAP refrigerants prevent supply shortages and price increases. Learn more about EPA refrigerant phaseout schedules.

c) Comply with safety requirements for A2L and A3 refrigerants

A2L (mildly flammable) and A3 (highly flammable) refrigerants require:

- Leak detection systems

- Charge limits based on space

- Safety labeling

- Technician training

d) Maintain audit-ready records for EPA SNAP compliance

Maintain for 3 years:

- Refrigerant purchase and use logs

- Service records

- Leak rate calculations

- Technician certifications

- Disposal records

SNAP and the AIM Act: Critical Connections

EPA SNAP rules, including Rule 26, work in tandem with the AIM Act to regulate refrigerants effectively.

Aligning SNAP rules with the AIM Act for unified refrigerant compliance

- SNAP: Approves SNAP-approved refrigerants for specific applications

- AIM Act: Reduces HFC supply through phasedown

This coordinated approach impacts refrigerant availability and compliance strategies for facility managers.

Manage HFC supply limits to stabilize operational costs

The AIM Act allocates HFC production and import rights, decreasing allowances over time. This has driven a 300-400% price increase for high-GWP refrigerants since 2021, affecting facility budgets.

Anticipate refrigerant shortages and price surges

Facility managers should anticipate:

- Rising costs for legacy refrigerants

- Seasonal supply shortages

- Growth in reclaimed refrigerants

- Accelerated adoption of low-GWP systems

Strategic planning is essential to maintain operational continuity.

Implementation challenges in SNAP Rule

Implementing the EPA SNAP program compliance presents challenges for facility managers, but targeted solutions can streamline the process.

a) Upgrade systems cost-effectively to meet SNAP standards

Old systems using R-404A drain your budget.

- Switch to SNAP approved refrigerants like R-448A or R-449A ($75–150/lb plus labor) to keep equipment running.

- Update systems by fixing valves and seals to meet SNAP refrigerant regulations.

- For bigger changes, choose low-GWP systems that save money within 3–7 years.

These steps cut costs and ensure compliance without downtime.

b) Equip technicians with certifications for safe refrigerant handling

Your team needs training to handle A2L and A3 refrigerants safely.

- Get EPA Section 608 and ASHRAE certifications to meet EPA SNAP program rules.

- Train on leak detection and safety using ACCA, AHRI, or manufacturer programs.

A skilled team keeps your facilities compliant and safe. Choose from the best refrigeration monitoring systems to keep you compliant with EPA rules.

c) Streamline record-keeping for multi-site compliance audits

Scattered records make audits stressful.

- Use Facilio to track refrigerant use, repairs, and certifications in one place.

- Review records quarterly to stay ready for EPA SNAP audits.

- Clear records save time and avoid penalties.

d) Control leaks to meet SNAP’s 20% threshold and avoid penalties

Leaks push you over SNAP’s 20% limit, risking fines. Learn how to detect leaks - Install infrared or ultrasonic detectors to catch leaks fast.

Set clear response plans and fix recurring issues. Calculate the HVAC refrigerant leak rates to stay aligned with SNAP refrigerant regulations.

How Facilio Helps You Stay Ahead of EPA SNAP Compliance

Keeping up with evolving EPA SNAP regulations—especially Rule 26—can be a major challenge, especially when you're managing multiple sites, refrigerant types, and compliance deadlines.

Manual processes and siloed systems only add to the complexity, putting your operations at risk of fines, inefficiencies, and environmental impact.

That’s where Facilio comes in.

Facilio’s connected refrigeration management platform is purpose-built to help facility and sustainability teams meet SNAP requirements with confidence—without overhauling your existing systems.

Here’s how Facilio makes compliance easy and scalable:

- Track SNAP Refrigerants at Scale Maintain a centralized, real-time view of all refrigerants—types, volumes, and locations—across your entire portfolio.

- Stay on Top of GWP and Rule 26 Requirements Instantly identify high-GWP refrigerants and prioritize SNAP-approved alternatives to meet regulatory goals under Rule 26 and the AIM Act.

- Automate Record-Keeping and Audit Readiness Capture service logs, leak repairs, and top-ups automatically. Be audit-ready at all times, with zero manual effort.

- Catch Leaks Before They Escalate Get real-time alerts from IoT-integrated leak detection systems to reduce emissions and avoid non-compliance.

- Simplify EPA Reporting Generate SNAP-compliant reports with just a few clicks using customizable templates—saving hours of back-and-forth.

- Stay Ahead of Regulatory Updates Proactive alerts keep your teams informed about refrigerant phase-outs and upcoming changes to SNAP rules.

- Plan Smart, Transition Smooth Use built-in analytics to plan your switch to low-GWP systems efficiently—minimizing disruptions and long-term costs.

Turn Compliance into a Competitive Advantage

EPA SNAP Rule 26 isn’t just about avoiding penalties—it’s about future-proofing your facilities, meeting ESG goals, and leading with operational excellence.

With Facilio, you get a single platform that simplifies compliance, reduces risk, and helps you run smarter, greener refrigeration systems across all your sites.

👉 Ready to see how it works?

👉 What is the EPA SNAP program?

The SNAP (Significant New Alternatives Policy) program, run by the EPA, reviews and approves refrigerants that are safer for the environment. If a refrigerant is SNAP-approved, it means it meets EPA’s standards for safety and environmental impact in specific applications.

👉 Why does the SNAP program exist?

SNAP helps phase out ozone-depleting substances and high-global warming potential (GWP) refrigerants. It pushes the industry toward more sustainable options—so you stay compliant and future-ready.

👉 What refrigerant regulations are coming in 2025?

2025 is a big year. Here’s what’s changing:

- The AIM Act mandates a 40% cut in HFCs (from baseline levels)

- Tighter leak repair rules for systems using A2L refrigerants

- More detailed record-keeping requirements

- And restrictions on using high-GWP refrigerants like R-404A

👉 What’s the EPA’s Technology Transition Rule?

This rule sets the timeline for switching from high-GWP refrigerants to cleaner alternatives. It applies to both new equipment and retrofits, so your planning needs to start now.

👉 What are the EPA rules for refrigerant leak repairs?

If your system holds 50 lbs or more, and the leak rate exceeds 20% (for commercial refrigeration), you must:

- Fix it within 30 days

- Log the repair, retest it, and document the leak rate. A2L refrigerants come with even stricter guidelines, so accurate tracking is a must.